MTS Aspirator Designer

Theory and Design

The MTS Aspirator is designed for a variety of applications in which oxygen transfer and mixing are required along with portability. This flexible, dependable aerator is best suited for deeper tanks that optimize the aeration and mixing zones while increasing oxygen utilization. The deep tank also minimizes land requirements which in turn often reduces overall construction cost.

Technology

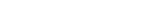

The MTS Aspirator design places the aerator at the bottom of the tank and creates distinct zones of influence. The Primary, or mixing zone, has the highest rate of oxygen transfer. The Secondary, or suspension zone, maintains solids suspension by providing energy for mixing and making optimal use of available oxygen.

Applications

The portable, flexible, multiple application design of the MTS Aspirator makes it the perfect choice for sludge holding tanks, aerobic digesters, activated sludge tanks, storage tanks, equalization basins, and post-aeration applications.

Determining Your Needs

Instructions

- Select you Liquid Depth with the drop-down.

- Select the MTM model that meets SOTR requirements.

- Read the model Horsepower.

Request yours Today

MTS ASPIRATOR

LAYOUT GUIDE

ZONES OF INFLUENCE

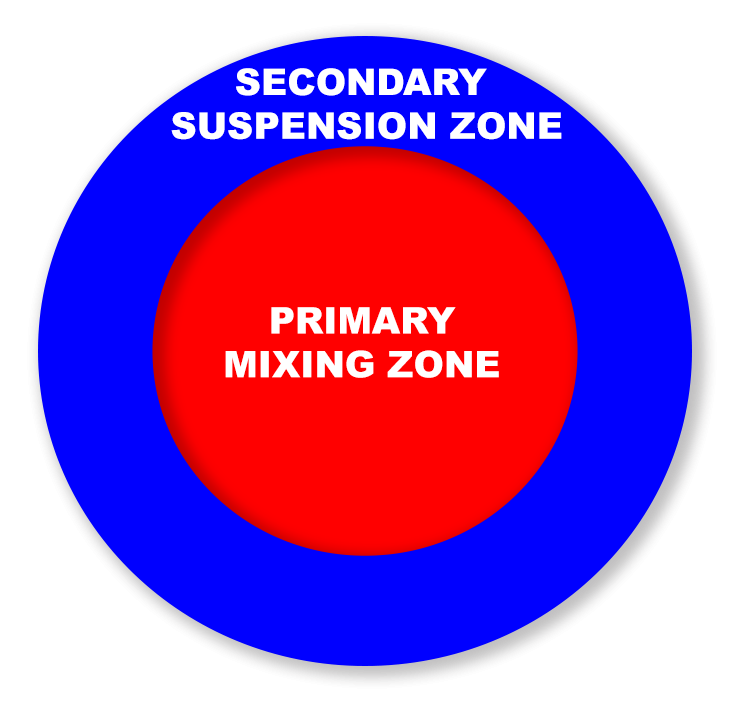

Primary Mixing Zone

of influence should be used to determine the maximum tank size for sludge holding tanks and aerobic digesters.

Secondary Mixing Zone

is used for the maximum mixing capacities in activated sludge, equalization, and waste holding tanks.

The Primary Mixing Zones should not infringe on one another when placing multiple units in a tank. Units should also be placed a minimum of one-quarter of the Primary Mixing Zone diameter from tank walls.